Stress (tension)

Sample environment equipment

Biaxial tensile testing machine

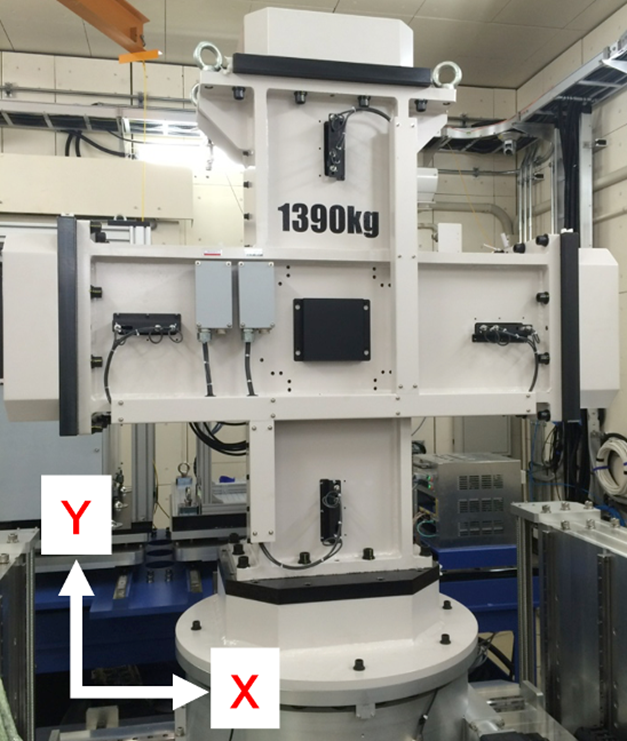

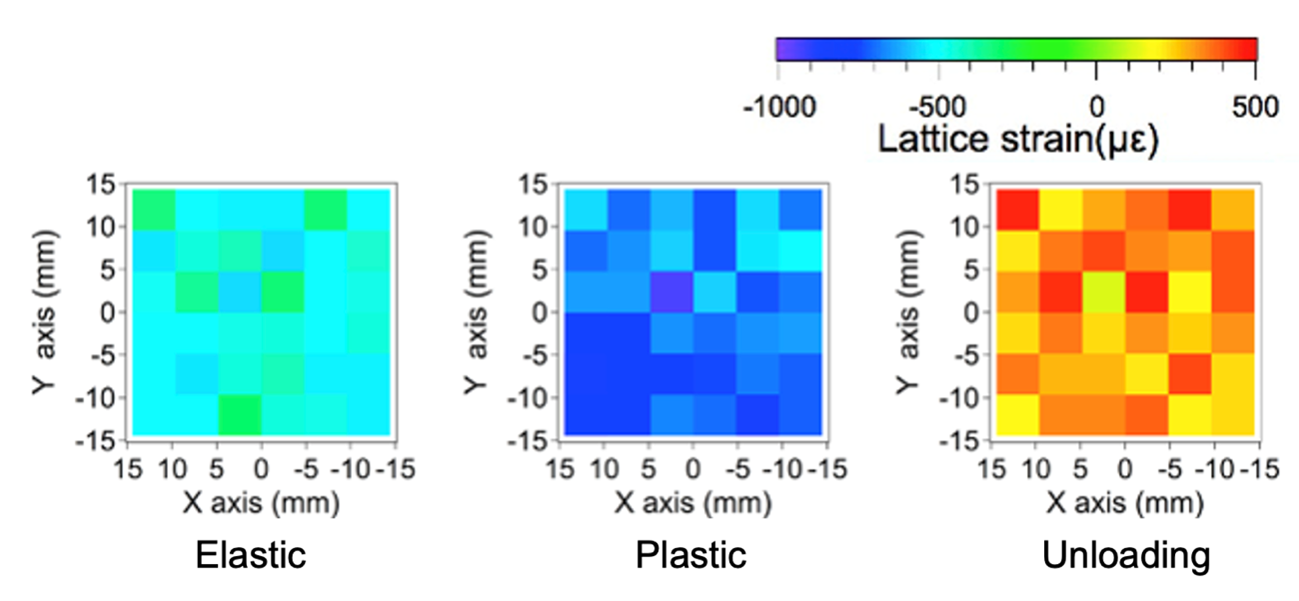

A biaxial tensile machine (BTM) can apply stresses in metallic materials in two directions and realize more realistic elastic-plastic deformation conditions close to the actual press-processing than using an uniaxial stress testing machine. The elastic-plastic deformation is characterized by microcrystalline structures, such as lattice distortion, dislocation density, and crystal grain size. It is of interest to reveal the two-dimensional distribution of these microcrystalline structures under biaxial stress conditions, and it is measured by the neutron imaging with the BTM.

Available instrument:BL22

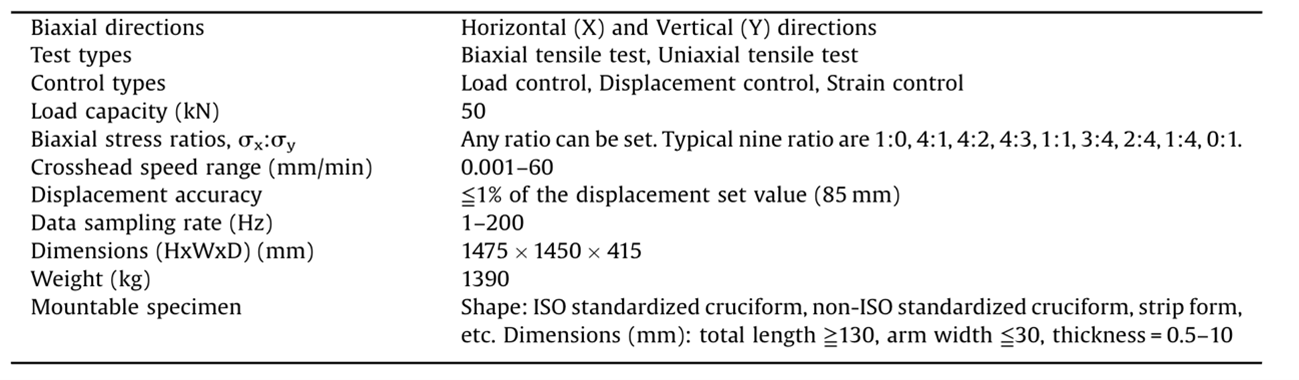

●Specifications

Biaxial tensile testing machine (BTM)

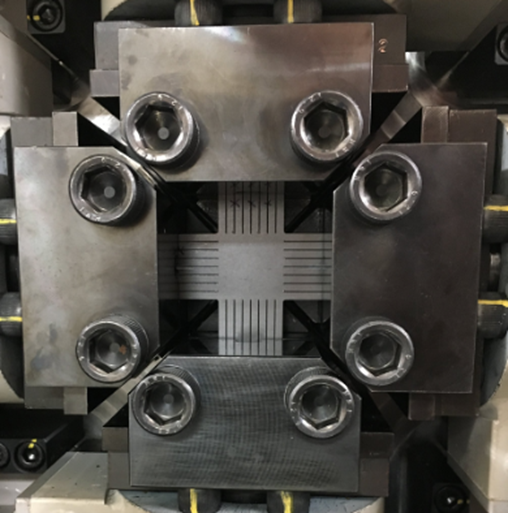

Cruciform specimen attached to the BTM.

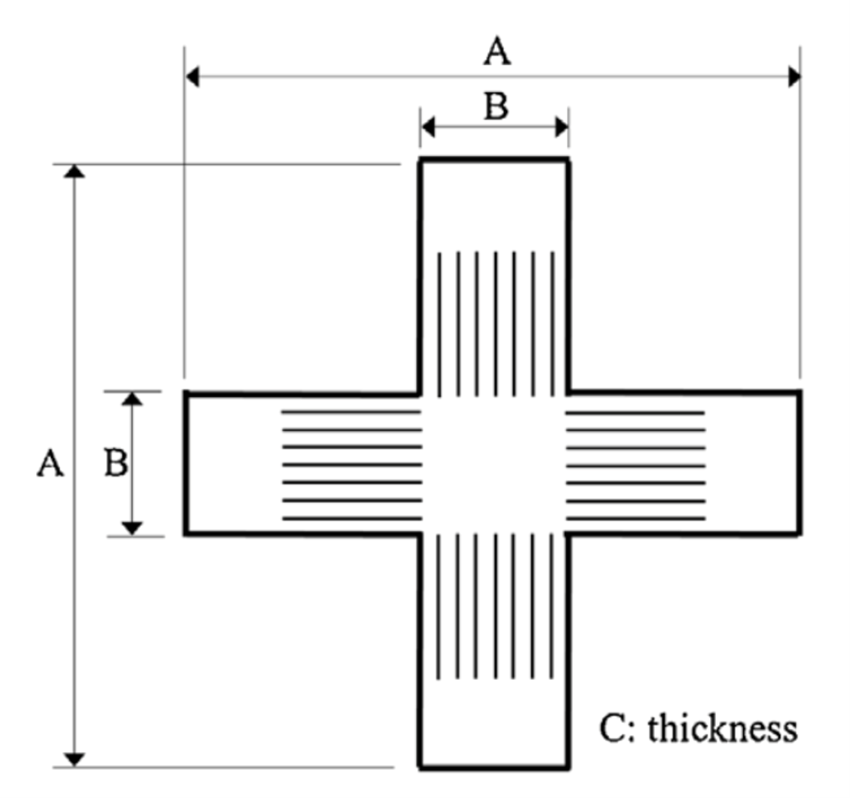

Cruciform specimen (A=130 mm, B=30 mm, C=0.4 to 10 mm). The shape of the specimen is defined by the ISO standards. Each arm of the cruciform specimen has seven slits.

Two-dimensional lattice strain distributions in elastic, plastic, and unloading states of high-tensile steel plate under biaxial stress state (σx:σy=1:1)

Members

Shuoyuan Zhang (CROSS)

References

[1] K. Kiriyama, S. Zhang, H. Hayashida, J. Suzuki, T. Kuwabara, "Development of a biaxial tensile testing machine for pulsed neutron experiments", MethodsX 6 (2019) 2166.